AC Drive or AC Variable Frequency Drive or AC VFD are the same terms used for a Power Electronic Instrument used to vary the speed of three-phase induction motor. The AC drive is consisting of the various circuitry and safety devices.

AC Drive are of various Capacity, Size, Ratings and so various Models for different applications.

As discussed earlier also that the main function of AC VFD is to control the rotational movement of any induction motor, but gradually with the evolution of AC drive, many safety and an advanced feature are incorporated in this instrument.

Principle of working of AC VFD/ AC Drive: –

Basic Principle of working of AC Drive /AC Variable Frequency Drive (VFD) is varying the Frequency of any induction motor with respect to Voltage or this can be described as when Voltage/ Frequency ratio when this ratio changed the rotational speed of the motor will get changed.

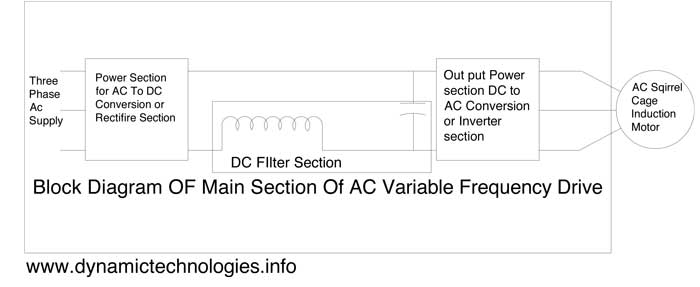

This AC Drive /AC Variable Frequency Drive (VFD) has majorly Three components.

-

The Power Conversion Section.

In this section input power is fed to the VFD and some protection circuitry is present to protect the further circuitry from the disturbance in Raw Power.

-

The Control Section.

In this section different type of circuitry is present according to different models for different application in the industry.

-

The Inverter Section.

Here in this section, the AC is converted into DC and the DC through chopper circuit and come to RC Circuit again

converted into AC with desired frequency.

Let us first know the various uses of AC Drive / AC VFD in different industry.

Application Of AC Drive/ AC VFD in industry and other areas.

Approximately in every other industry, Ac drive / VFD is used for motion control, Speed Control or position control. Virtually we cannot imagine any industry without AC Drive / VFD. Let us name some of them.

- Steel Industry uses AC Drive / VFD for all possible uses i.e. motion control, Speed Control and position control.

- Paper Industry uses AC Drive / VFD for all possible uses i.e. motion control, Speed Control and position control.

- Sugar Industry uses AC Drive / VFD for all possible uses i.e. Torque control, Speed Control.

- HVAC Industry uses AC Drive / VFD for all possible uses i.e. Speed Control of fan and Torque control for compressors.

- Cable Industry uses AC Drive / VFD for all possible uses i.e. motion control, Speed Control and position control.

- Garment Industry uses AC Drive / VFD for all possible uses i.e. motion control, Speed Control and position control.

- Printing Industry uses AC Drive / VFD for all possible uses i.e. motion control, Speed Control and position control.

- Automobile Industry uses AC Drive / VFD for all possible uses i.e. motion control, Speed Control and position control.

- Pharmaceutical Industry uses AC Drive / VFD for all possible uses i.e. motion control, Speed Control and position control.

- Petrochemical Industry uses AC Drive / VFD for all possible uses i.e. motion control, Speed Control and position control.

So this is the list of some of the industries. The list is big and difficult to accumulate in once.

Benefits Of AC Drive / AC Variable Frequency Drive (VFD)

- Motion And Speed Control – Without AC Drive it was very difficult to vary the speed of any machine previously it was done with the different combination of gears which was a time taking process nowadays it is very simple to vary the speed of any motor hence the speed of the machine.

- Energy Savings – As we reduce the speed of any Induction motor with the help of AC Drive / AC Variable Frequency Drive (VFD), actually we reduce the effective Kw Rating of motor so we save electricity in kW.

- Low risk of Peak Load Penalty – When we use AC Drive /AC Variable Frequency Drive (VFD) then there is no possibility of high inrush current because of that particular motor, so virtually there is no possibility of Peak Load Penalty.

- Low risk of thermal and mechanical stress– When we use AC Drive /AC Variable Frequency Drive (VFD) then there is no possibility of high mechanical stress on the mechanical system as well as electrical stress on the Electrical system.

- No risk of low Power factor Penalty – When we use AC Drive /AC Variable Frequency Drive (VFD) then there is no possibility of Power factor penalty because in ac drive when we convert ac to dc and then further DC To AC the power factor will always be unity at the source end so there will be no chance of low power factor penalty.

- Less Expense on wire and cable – When we use AC Drive /AC Variable Frequency Drive (VFD) then there will be unity power factor and low inrush currents so there is no requirements of using extra wire and cable size which is the common practice in the industry to avoid any chances of extra unexpected load on system low voltage or low Power factor.

Variable Speed Capacity Control- For centrifugal pumps, fans and compressors, the ideal fan (affinity) laws describe how speed affects flow, head and power consumption (Table -1 ).

Table -1. Effects of Changes in Fan Speed

| Flow changes linearly with speed | Flow Rate2 = Flow Rate1 x (RPM2/RPM1) |

| Head varies as the speed squared | Lift2 = Lift1 x (RPM2/RPM1)2 |

| Power varies as the speed cubed | Power2 = Power1 x (RPM2/RPM1)3 |

AC Drive As starter –

Use of AC Drive /AC Variable Frequency Drive (VFD) as a starter is a wise move because if we compare the AC Drive with other types of starters we see that it is a drastic difference in inrush current.

We are trying to explain this with the help of following chart.

| Sr. No. | Type Of Starter | % OF Full Load Current |

| 1. | AC Drive / Variable Frequency Drive (VFD) | 100 % |

| 2. | Star / delta Starter | 200%- 300% |

| 3. | Solid State Soft Starter | 200%-@250% |

| 4. | Auto Transformer Starter | 450%-500% |

| 5. | DOL Starter | 800%-900% |

Conclusion:-

By Above chart And Discussed Facts here is the concussion

- AC Drive /AC Variable Frequency Drive (VFD) is the most energy-efficient means of control.

- AC Drive /AC Variable Frequency Drive (VFD) Reduce the thermal and mechanical stress on the system.

- AC Drive /AC Variable Frequency Drive (VFD) Provides the highest power factor and there is no need of separate capacitors or power factor correction panels in the system.

- AC Drive /AC Variable Frequency Drive (VFD) provides low Kva and saves energy.

- AC Drive /AC Variable Frequency Drive (VFD) saves the capital cost involvements in not only generation back up but also in wire and cable sizing.